Process Control Didactic Trainer System

TEMPERATURE PROCESS CONTROL TRAINER (LIQUID)

KPC-01

- Temperature Process Control Trainer is designed for understanding the basic temperature control principles for the Process control, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Temperature Transmitter Two Wire Type RTD-PT100, Range 0-100 DegC, Output 4–20 mA

- Transparent Measuring Tank with Heater, Stirrer and Sensor.

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

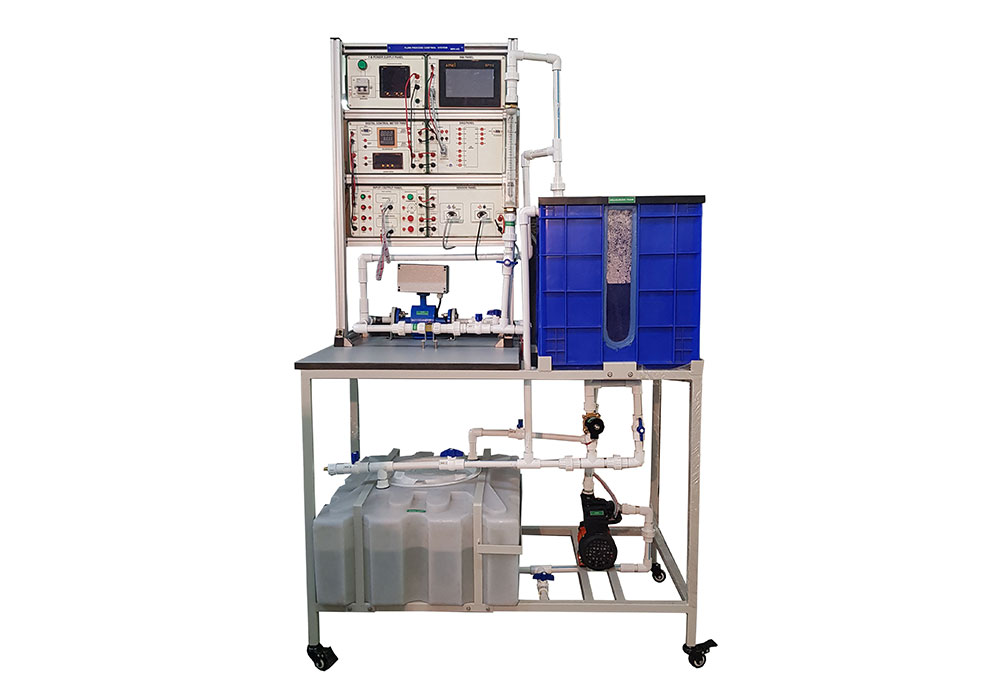

FLOW PROCESS CONTROL TRAINER (LIQUID)

KPC-02

- Flow Process Control Trainer is designed for understanding the basic flow control principles for the Process control, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Turbine Flow Transmitter Type Two wire, Range 10-100LPM, Output 4– 20 mA

- Transparent Measuring Tank.

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

TEMPERATURE PROCESS CONTROL TRAINER (AIR)

KPC-03

- Temperature Process Control Trainer is designed for understanding the basic temperature control principles for the Process control, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Temperature Transmitter Two Wire Type RTD-PT100, Range 0-100 DegC, Output 4–20 mA

- Temperature Transmitter Two Wire Type K Thermocouple, Range 0-100 DegC, Output 4–20 mA

- Process Chamber with Heater, Temperature Sensor & Fan Assemblies

PID Process Control Trainer

KPC-03C

- Temperature Process Control Trainer is designed for understanding the basic temperature control principles for the Process control, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in Powder Coated MS Enclosure with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Process Chamber with Heater, Temperature Sensor & Fan Assemblies

LEVEL PROCESS CONTROL TRAINER (LIQUID)

KPC-04

- Level Process Control Trainer is designed for understanding the basic Level control principles for the Process control mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Level Transmitter Type Electronic, Two wire, Range 0–300 mm, Output 4–20mA,

- Electro Pneumatic Converter (I/P): Input 4-20mA, Output 3-15 psig

- Control Valve Type Pneumatic, Size 1/2", Input 3–15 psig, Air to Open, Characteristics Linear

- Air Filter Regulator with Air Compressor 8 bar

- Transparent Measuring Tank with Sensor.

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

MULTI PROCESS CONTROL TRAINER (LIQUID)

KPC-04M

- Multi Process Control Trainer is designed for understanding the Level/flow/Pressure/Temperature control principles for the Process control mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital Data Acquisition Controller with Voltage/Current Analog Input/Output, Digital Input & SSR/Relay Output.

- Level transmitter Type Two wire, Range 0–300mm, Output 4 – 20 mA

- Flow transmitter Type Two wire, Range 10-100LPM, Output 4 – 20 mA

- Pressure transmitter Type Two wire, Range 0-5bar, Output 4–20 mA

- Temperature transmitter Type Two wire, Range 0-100 DegC, Output 4–20 mA

- I/P converter Input 4-20mA, Output 3-15 psig x 2No’s

- Control valve Type Pneumatic, Size 1/2", Input 3–15 psig, Air to open, Char. Linear x 2No’s

- Air Filter Regulator Range 0-2.5 kg/cm2

- Air Compressor 8 bar, 50 LPM, 30 Liters, 230V, 50 Hz, with Pressure Regulator

- Process Measuring Tank with Sensors, Heater and Stirrer

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

PRESSURE PROCESS CONTROL TRAINER (AIR)

KPC-05

- Pressure Measurement trainer is designed for Understanding the basic Level control principles for the Pressure Process control mounted on Aluminum Profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Pressure Transmitter: Type Two wire, Range 0–5 Bar, Output 4–20 mA

- Electro Pneumatic Converter (I/P): Input 4-20mA, Output 3-15 psig

- Control Valve Type Pneumatic, Size 1/2", Input 3–15 psig, Air to Open, Characteristics Linear

- Air Filter Regulator with Air Compressor 8 bar

- MS Process Tank Pressure Vessel with Output Solenoid Valve

PNEUMATIC CONTROL VALVE TRAINER (LIQUID)

KPC-06P

- Pneumatic Control Valve Characteristics trainer is designed for understanding the basic control valve principles and its flow characteristics, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Level Transmitter Type Electronic, Two wire, Range 0–300 mm, Output 4–20mA

- Industrial Type Pneumatic Control Valve of equal %,Liner %,ON/OFF to be mounted in parallel line

- Electro Pneumatic Converter (I/P): Input 4-20mA, Output 3-15 psig

- Control Valve Type Pneumatic, Size 1/2", Input 3–15 psig, Air to Open, Characteristics Linear

- Air Filter Regulator with Air Compressor 8 bar

- Transparent Measuring Tank with Sensor.

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

ELECTRICAL CONTROL VALVE TRAINER (LIQUID)

KPC-06E

- Electrical Control Valve Characteristics trainer is designed for understanding the basic control valve principles and its flow characteristics, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Level Transmitter Type Electronic, Two wire, Range 0–300 mm, Output 4–20mA

- Industrial Type Electrical Control Valve ON-OFF type Ball Valve & Butterfly Valve to be mounted in parallel line

- Transparent Measuring Tank with Sensor.

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

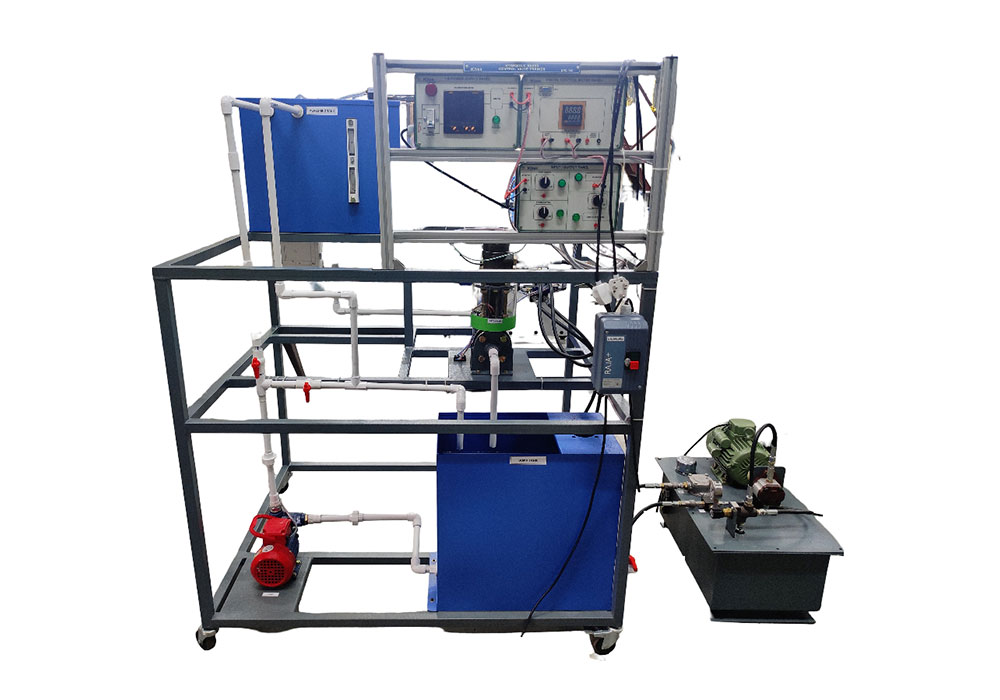

HYDRAULIC CONTROL VALVE TRAINER (LIQUID)

KPC-06H

- Hydraulic Control Valve Characteristics trainer is designed for understanding the basic control valve principles and its flow characteristics, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Level Transmitter Type Electronic, Two wire, Range 0–300 mm, Output 4–20mA

- Industrial Type Hydraulic Gate Control Valve ON-OFF type.

- Hydraulic Power Pack with 1Hp AC Motor coupled with 3LPM Gear Hydraulic Pump along with Pressure Relief valve, Filter & Oil Level Indicator, P & T Port.

- Transparent Measuring Tank with Sensor.

- Sump Tank with Water Pump, Solenoid Valve & Rotameter.

P-I & I-P CONVERTER TRAINER

KPC-07

- P to I & I to P Converter Trainer is designed for understanding basic principles of electronic and pneumatic signal conversion, mounted on Aluminum profile rack with sturdy table top flat panel

- Process Control Trainer having control panel provided in 30X30mm Aluminum profile rack with sturdy table top flat panel.

- Electrical Control Panels are provided in powder Coated SS Enclosure Mounted on the aluminum rack with mimic diagram

- All input & output are terminated in 4mm BS-10 shrouded / 2mm banana connector, provided with 4mm shrouded / 2mm banana cable for experiments.

- Digital PID Controller with Dual Display, Voltage/Current Input, SSR/Relay Output,

- Pressure Transmitter: Type Two wire, Range 0–1 bar, Output 4–20 mA

- Electro Pneumatic Converter (I/P): Input 4-20mA, Output 3-15 psi

- Pressure to Current Converter (P/I): Input: 3-15 psi, output 4-20Ma

- Digital Calibrator Measure/source, milliamp/millivolt mode

- Air Filter Regulator with Air Compressor 8 bar

- MS Process Tank Pressure Vessel with Output Solenoid Valve

PROCESS CONTROL FOR COUPLED TANK SYSTEM TRAINER

KPC-02C

- Analog Input

- Channels: 6 (Differential)

- Range: 0 to 20 mA, 4 to 20 mA

- Resolution: 16-bit

- Analog Output

- Channels: 2

- Range: 0 to 20 mA, 4 to 20 mA

- Resolution: 12-bit

- Digital Input

- 100 Hz, 8 channel

- Open collector, 8 channel

- Analog Input

- Channels: 6 (Differential)

- Range: 0 to 20 mA, 4 to 20 mA

- Resolution: 16-bit

- Frequency: 3 MHz with 16x2 LCD Display

- Ethernet Ports: RJ-45, 10/100 Base-TX

- Protocol: Modbus TCP, Modbus UDP

- 2-way Isolation: Ethernet 1500 VDC, I/O 2500 VDC

- Tanks & Valves

- 3 Transparent Measuring Tanks, each with 2 Capacitive Proximity Sensors & a 230V Solenoid Valve

- 1 Transparent Mixing Tank with 3 Capacitive Proximity Switches, 230V Solenoid Valve, and Stirrer

- 230V Solenoid Valve × 2 nos

- Pump & Sump Tank

- SS Sump Tank, 30 Liter capacity

- Water Pump, 0.5 hp

- Flow Measurement

- Rota-meter: 10–200 LPH with manual hand control valve

- Construction

- Piping Material: Stainless Steel

- Ethernet Port for PC communication with Windows-based PID software

- Power Supply Unit: Input 85–265 V AC, Output 24 V DC, Max. 4.5 A, short-circuit-proof

- Trainer Design

- Control panel mounted on 30×30 mm aluminum profile rack with sturdy table-top flat panel and castor wheel table

- ABS plastic panel mounted on aluminum rack with mimic diagram

- All input & output terminated in 4 mm shrouded connectors

- Supplied with 4 mm banana cables for experiments

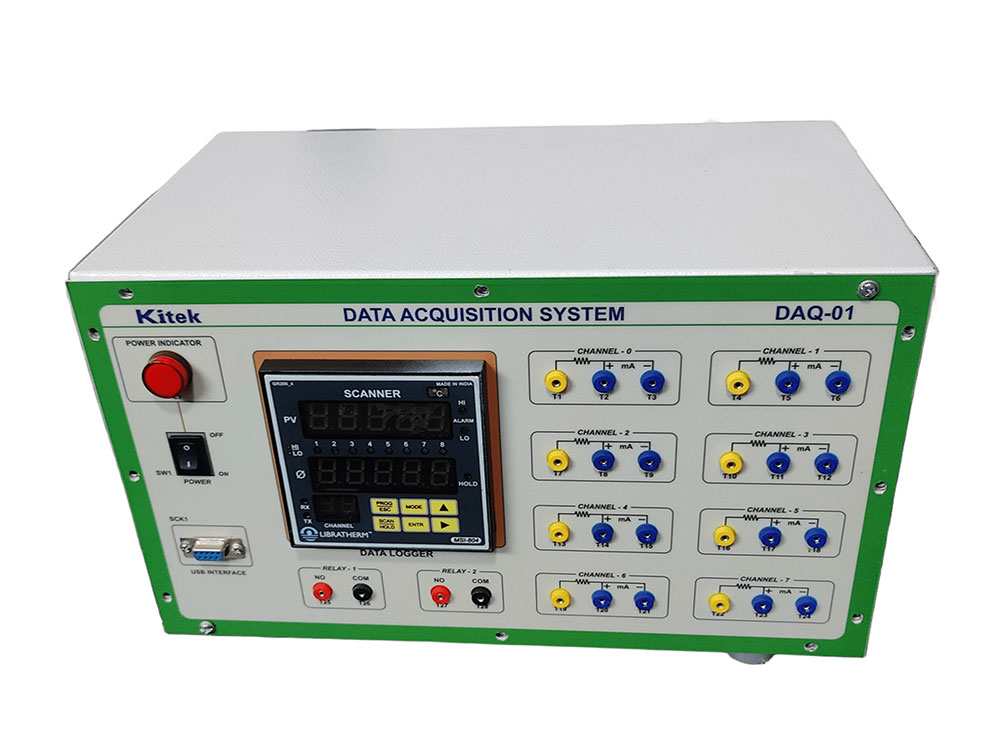

DATA ACQUISITION SYSTEM TRAINER

DAQ-01

- Number of Channels: 8 nos.

- Universal Input Type: RTD (Pt-100), (4–20) mA

- Range: 0 to 9999 or -9999 to +9999 UOM

- Accuracy: Better than ±0.1 °C, ±1 °C (software linearized for temperature)

- Display:

- 5-digit, 0.5” 7-segment Red/Green LED for process, alarm values, and real-time clock

- 2-digit, 0.3” 7-segment Red LED for channel number

- Scan Rate: 1 to 99 sec (programmable through front panel keyboard)

- Data Storage Interval: 1 to 99 minutes (user-programmable)

- Data Storage Capacity: 8000 records (512 KB)

- Print Interval: 1 to 99 minutes (user-programmable)

- Skip/Hold Facility: Available through keyboard in configuration mode

- High / Low Alarm: Common or individual settable using keypad

- Common Relay Output: 2 nos., potential-free changeover contacts

- LED Indication: 8 dual-color LEDs on front panel indicating status of each alarm output

- Serial Interface: RS485 MODBUS RTU protocol in slave mode for PC interface

- Power Supply: 90–260 VAC ±10% (10 VA), 50/60 Hz or 24 VDC/AC @ 200 Ma

DATA ACQUISITION AND CONTROL TRAINER

DAQ-02

- Analog Input

- Channels: 6 (Differential)

- Range: ±150 mV, ±500 mV, ±5 V, ±10 V, 0 to 20 mA, 4 to 20 mA

- Resolution: 16-bit

- Analog Output

- Channels: 2

- Range: ±10 V, 0–10 V, ±5 V, 0–5 V, 0 to 20 mA, 4 to 20 mA

- Resolution: 12-bit

- Digital Input

- 100 Hz, 2 channel

- Open collector, 2 channel

- Sensors

- Pressure Sensor: 0–10 bar with pressure generator

- Temperature Sensor: 0–100 °C with heater, fan, and chamber

- Communication

- Ethernet Port: Supports TCP Modbus protocol

- Windows-based application software with library

- Power Supply

- 230V AC for operation

- Construction

- Housed in a metal enclosure

- All inputs and outputs terminated in 4 mm shrouded connectors

- Supplied with 4 mm banana cables for experiments