Sensor Trainer System

Instrumentation & Control Didactic trainer

DISPLACEMENT MEASUREMENT USING LVDT TRAINER KIT

ITK-01

- LVDT Transducer with transparent enclosure having Displacement of ± 5mm

- Primary Excitation voltage of Sine wave 1V p-p

- On-board Digital Panel Meter provided using AD7135

- Screw Gauge for reference displacement reading

- On board 1 KHz Sine wave generator for excitation.

- Onboard Instrumentation Amplifier provided

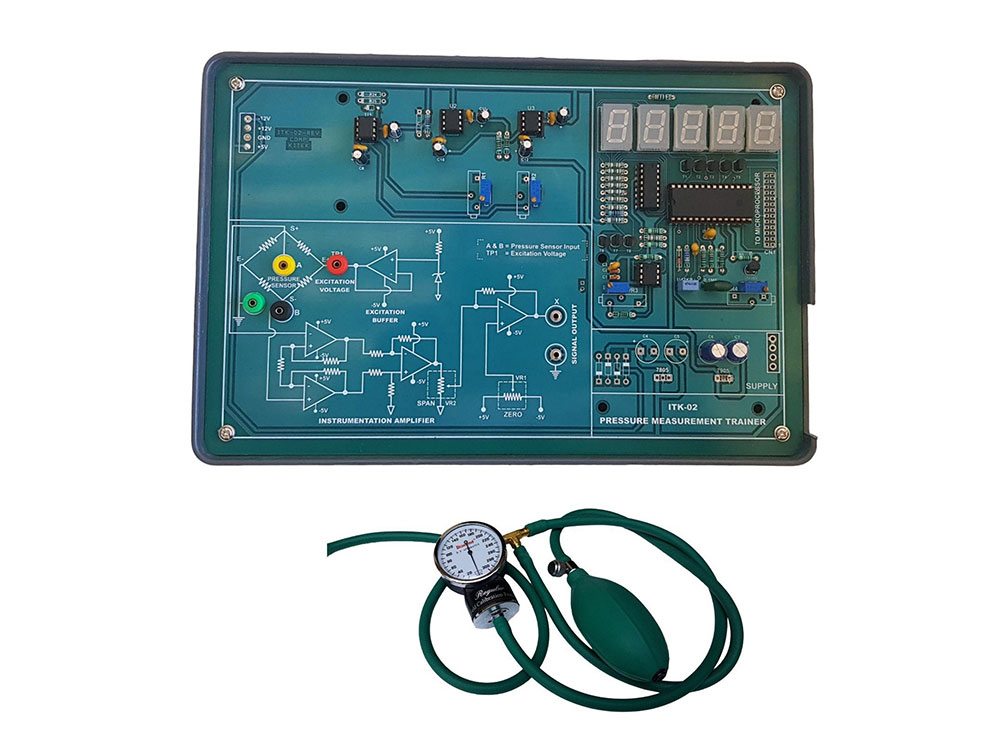

PRESSURE MEASUREMENT KIT

ITK-02

- Resistive Pressure Transducer with Pressure of 0-300mm hg / 6psi

- Primary Excitation voltage of 5V DC on board provided.

- On-board 41/2 Digital Panel Meter provided using AD7135.

- Pressure generation and Monitor using a Pressure gauge.

- Onboard Instrumentation Amplifier provided

LOAD MESAUREMENT USING Strain Gauge KIT

ITK-03

- Resistive cantilever type Load cell is used to measured up to 3 KGs.

- Primary Excitation voltage of 12V DC provided on board.

- On-board 41/2 Digital Panel Meter provided using AD7135.

- Onboard Instrumentation Amplifier provided

- Weights can be verified by Physical counting of weights

Thermocouple Trainer Kit

ITK-04

- K-type Thermocouple is used to measurement Temperature up to 100ºC

- On-board 41/2 Digital Panel Meter provided using AD7135.

- Onboard Instrumentation Amplifier provided

- Thermometer for measurement of temperature

- Water Heater with AC mains Chord provided

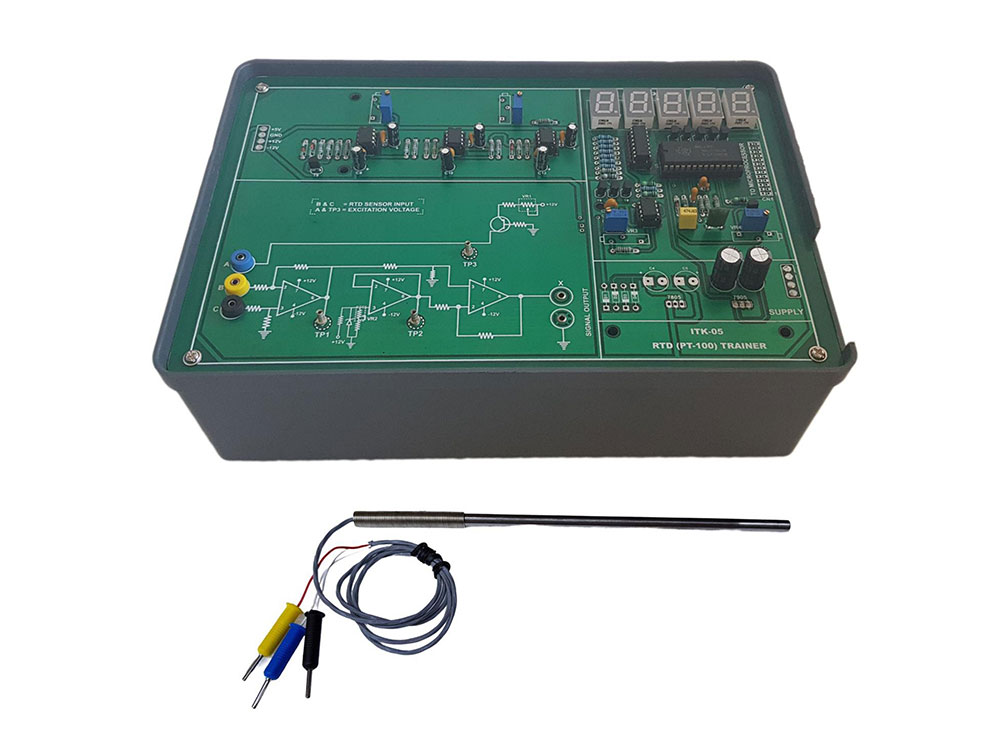

RTD Trainer Kit

ITK-05

- PT-100 Type RTD sensor is used to measurement Temperature up to 100ºC

- On-board 41/2 Digital Panel Meter provided using AD7135.

- Onboard Instrumentation Amplifier provided

- Thermometer for measurement of temperature

- Water Heater with AC mains Chord provided

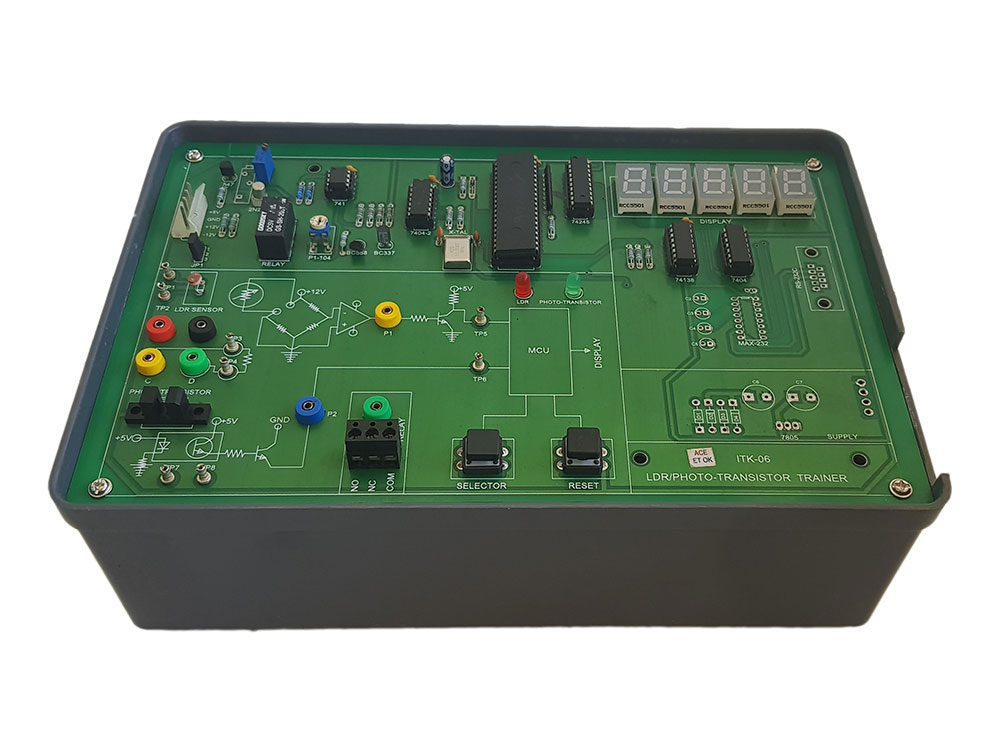

LDR TRAINER KIT

ITK-06

- Sensor

LDR or Photo-Transistor is used for light sensing - Measurement Options

Output available on 2mm Banana sockets for Monitoring

Relay output for Alarm indication - Onboard Features

On Board Relay provided to explain the function of LDR

Onboard Instrumentation Amplifier provided

Block Description Screen printed on glassy epoxy PCB

Level Indicator Kit

ITK-07

- Capacitive Level Transducer to Measure Level up to 100mm.

- On-board 41/2 Digital Panel Meter provided using AD7135.

- Onboard Instrumentation Amplifier provided

- 100mm Scale is provided for level measurement

- Plastic container with outlet Tap is provided for Water Storage

Speed Measurement Kit

ITK-08

- Magnetic Pick-up & Photo Pick up Transducer is also used

- On-board Digital RPM Panel Meter provided

- Onboard Instrumentation Amplifier provided

- 6V DC Motor with necessary attachment is provided

ANGULAR DISPLACEMENT Kit

ITK-10

- Resistive Transducer using multi turn potentiometer to measure Angle from 0° to 360°.

- Protractor for angle measurement

- Onboard Instrumentation Amplifier provided

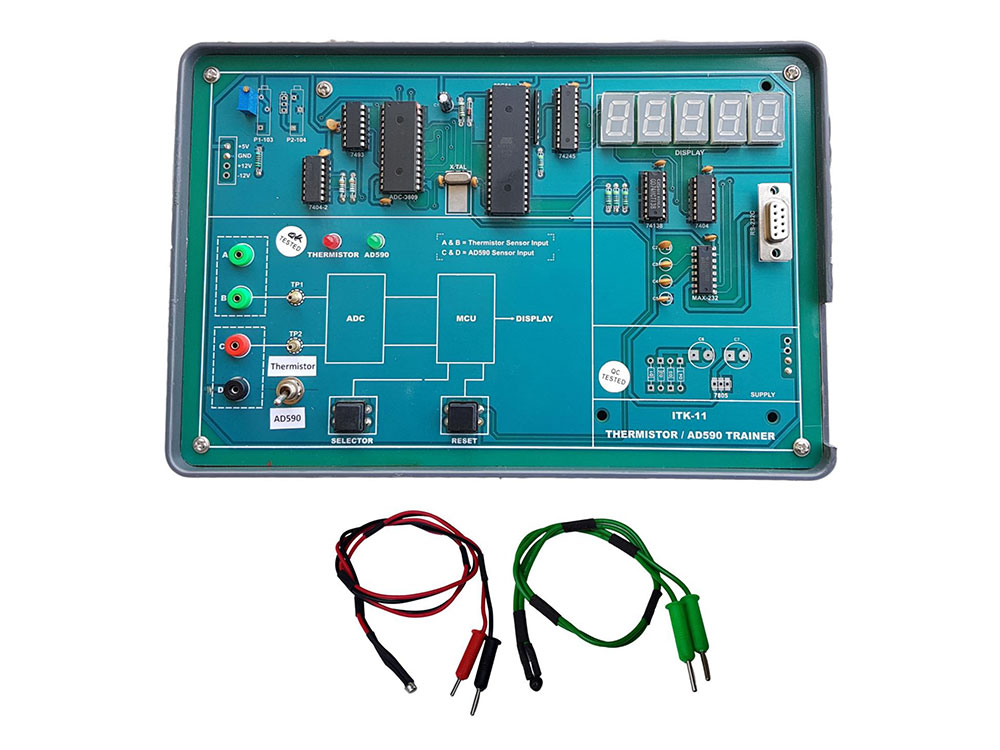

Thermistor / AD590 Kit

ITK-11

- AD590 /Thermistor Sensor is used to measure temperature up to 100ºC

- Onboard Instrumentation Amplifier provided

- 12V Heater provided on board.

ULTRASONIC TRANSDUCER

ITK-14

- Transducer Ultrasonic Transducer.

- 40KHz Oscillator

- Measurement Options

- Output available on 2mm Banana sockets for Monitoring

- Seven Segment Display for Distance Measurement

- Measurement Range

- Onboard Features

- On board LED Seven Segment Display provided.

- Onboard Ultrasonic Transmitter & Receiver Provided.

- Block Description Screen printed on glassy epoxy PCB

- Interconnections

- All interconnections are made using 2mm banana Patch cords.

- Test points are provided to analyze signals at various points.

- All ICS are mounted on IC Sockets.

- Bare board Tested Glass Epoxy SMOBC PCB is used.

- In-Built Power Supply of +5V & 12V/250mA with Power ON indication

- Attractive ABS enclosures.

- Set of 2mm Patch cords for interconnections

FLOW MEASUREMENT TRAINER

ITK-15

- Measurement Options

- On-board Rota meter provided to measure Flow of water in LPM.

- On Panel Features

- Two Tanks Provided.

- 0.5 HP Motor is provided for filing up the tank.

- Rota meter provided to measure the flow of liquid.

- Two valves provided for controlling the fluid flow through pipe

- Potentiometer for controlling speed of fluid through pump

- Digital Panel meter for flow measurement

- Signal conditioning circuit

- Open Top water tank

- Push Button on front panel to reset counter

- Interconnections

- All interconnections are made using 2mm banana Patch cords.

- Separate ON/OFF switch for pump & trainer

- Test points are provided to analyze signals at various points.

- All ICS are mounted on IC Sockets.

- Bare board Tested Glass Epoxy SMOBC PCB is used.

- In-Built Power Supply of +5V/1.5A, ±12V/250mA with Power ON indication

- Attractive ABS Plastic enclosures.

- Set of 2mm Patch cords for interconnections

- User’s Manual

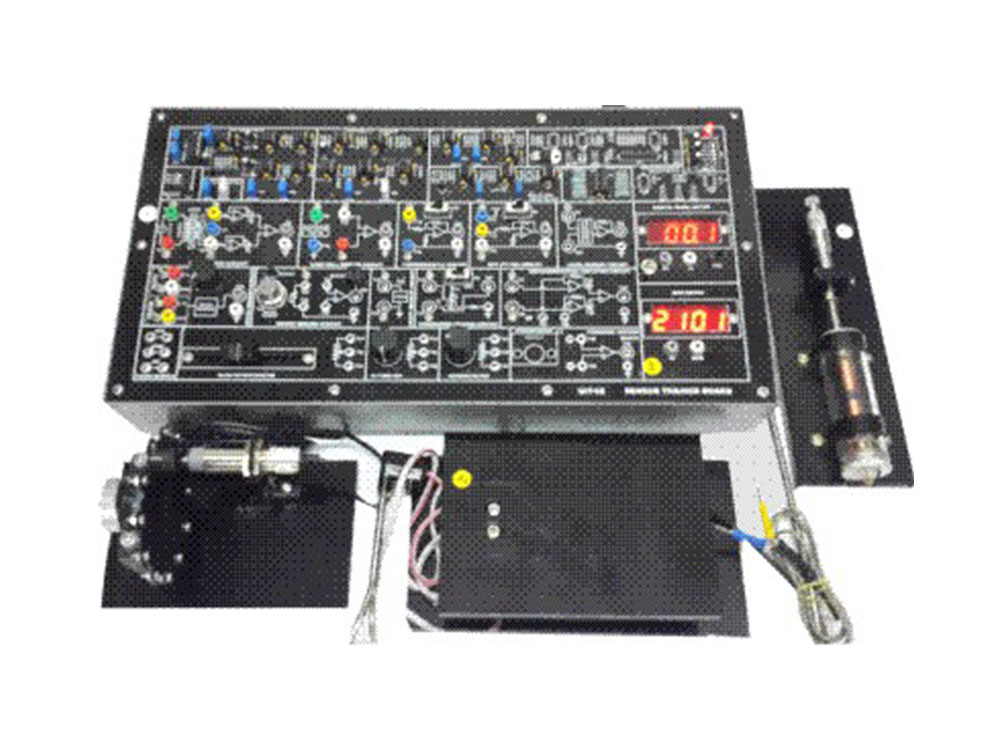

SENSOR TRAINER BOARD

UIT-02

- On-board Digital Panel Meter provided

- Input available on 2mmBanana sockets

- Compatible LVDT Transducer, Pressure Transducer, Strain/Load Cell Transducer,

- Temperature Sensor, Level Sensor, Speed Sensor, Smoke Sensor

- On-board Signal Conditioning Amplifier

- On-board Instrumentation amplifier

- All interconnections are made using 2mm banana Patch cords.

- Test points are provided to analyze signals at various points.

- All ICS are mounted on IC Sockets. Bare board Tested Glass Epoxy SMOBC PCB is used.

- In-Built Power Supply of ±5V, ±12V.

- Attractive Metal Enclosure, User Manual for Experiments.

SENSOR TRAINER

UIT-03

- Trainer having control panel should be provided in 30X30mm Aluminum profile rack or MS Enclosure with sturdy table top flat panel.

- Should use Plated-through Hole (PTH) Bare Board Tested Printed Circuit Board

- Should have ABS plastic panel mounted experimental Modules

- All input & output are terminated in 2mm banana connector; Provide 2mm banana cable for experiments.

- Sensor Trainer (Main Unit)

- Instrumentation Amplifier, Differential Amplifier, Amplifier with Gain & Offset, X100 Amplifier, Power Amplifier, Current Amplifier, AC Amplifier, Summing Amplifier

- 1 to10KHz Sine Wave Generator, Max 7.5Vpp Amplitude

- 10KΩ Multi turn Pot, 10KΩ Wire Wound Pot,10KΩ Linear Variable Slide Pot

- 40 KHz Oscillator, 40 KHz Filter, Buffer, Inverter, Electronic Switch, Comparator, Full wave Rectifier, Low Pass filter.

- On Board Fixed DC Power Supply of ±5V/1A, ±12V/1A

- Glass Epoxy (PTH) Bare Board Tested Printed Circuit Board Panel

- Enclosed in a Metal Powder Coated Enclosure

- Data Acquisition System (UIT-DAQ)

- Analog Input: ADC 4 Channel (Single Ended) / 2 Channel (Differential), 16-bit Resolution

- Analog Output: DAC 2 channel, 16-bit Resolution

- Digital Input: 4 Channel

- Digital Output: 4 Channel

- Measurement: 32 bit Frequency / RPM counter (1 Channel)

- 7 Inch IOT Based Graphical Touchscreen HMI Display

- Connectivity: HDMI, USB & RJ45 (Ethernet)

- Glass epoxy (PTH) Bare Board Tested Printed Circuit Board Panel

- Sensor Measurement Data Acquisition Software: Windows 10, displays X-T, Digital values & Saves data

- Enclosed in a Powder coated MS enclosure

- Sensor Accessories for Measurement

- Temperature Heater Unit with Thermistor, LM335, AD590, PT-100, Thermocouples

- LVDT Unit with Screw gauge to measure scale Range: ±5mm

- Load Cell Unit with Maximum load : <3Kg with 4 different value Weight

- Light Source Unit with LDR, Photovoltaic, Photo Diode, Photo transistor sensors & Light bulb Luminous intensity adjustable

- Speed Measurement Unit for +5V DC Motor with slotted disc having sensor like Photo Pickup, Proximity Sensors

SENSOR TRAINER

UIT-03A

- Trainer having control panel should be provided in 30X30mm Aluminum profile rack or MS Enclosure with sturdy table top flat panel.

- Should use Plated-through Hole (PTH) Bare Board Tested Printed Circuit Board

- Should have ABS plastic panel mounted experimental Modules

- All input & output are terminated in 2mm banana connector; Provide 2mm banana cable for experiments

- Sensor Trainer (Main Unit)

- Instrumentation Amplifier, Differential Amplifier, Amplifier with Gain & Offset, X100 Amplifier, Power Amplifier, Current Amplifier, AC Amplifier, Summing Amplifier

- 1 to10KHz Sine Wave Generator, Max 7.5Vpp Amplitude

- 10KΩ Multi turn Pot, 10KΩ Wire Wound Pot,10KΩ Linear Variable Slide Pot

- 40 KHz Oscillator, 40 KHz Filter, Buffer, Inverter, Electronic Switch, Comparator, Full wave Rectifier, Low Pass filter.

- On Board Fixed DC Power Supply of ±5V/1A, ±12V/1A

- Glass Epoxy (PTH) Bare Board Tested Printed Circuit Board Panel

- Enclosed in a Metal Powder Coated Enclosure

- Sensor Accessories for Measurement

- Load Cell Unit with Maximum load : <3Kg with 4 different value Weight

- Temperature Heater Unit with Thermistor, LM335, AD590, PT-100, Thermocouples, Bimetallic

- Pressure generator Unit with Pressure gauge to generate pressure up to 6PSI.

- LVDT Unit with Screw gauge to measure scale Range: ±5mm

- Light Source Unit with LDR, Photovoltaic, Photo Diode, Photo transistor sensors & Light bulb Luminous intensity adjustable

- Angle/Error Measurement Unit having 2 no’s of Servo potentiometer with adjustable Angular angle: 0~360°

- Speed Measurement Unit for +5V DC Motor with slotted disc having sensor like Photo Pickup, Proximity Sensors

- Water Level measurement Unit having Acrylic Tank for water Level measurement with 10cm Water level scale

- Ultrasonic transmitter/receiver: nominal frequency= 40 KHz with Platform moving range 200mm

INDUSTRIAL ANALOG SENSOR TRAINER

UIT-04

- Trainer having control panel should be provided in MS Enclosure with sturdy table top flat panel.

- All input & output are terminated in 2mm banana connector; Provide 2mm banana cable for experiments.

- Power Supply Unit 230V/50Hz AC Socket.

- One Pilot Lamp to indicate Power input.

- 24V/2A Fixed DC Output & 0-10V Variable DC Output

- NPN & PNP Input / Output for Proximity Sensor with Pilot Lamp

- DC Motor Unit 24V DC Motor with Speed Control Potentiometer

- One Pilot Lamp to indicate Power Input

- Counter Unit

- 230V/50Hz AC Socket

- Seven Segment Display to measure the event count.

- 1 No Analog Distance Sensor

- 1 No Analog Ultrasonic Sensor

- 1 No Load/Strain measuring unit with display load / strain amplifier

- 1 No Analog Inductive Sensor (M12)

- 1 No Analog Inductive Sensor (M18)

- 1 No Ultrasonic Distance Measurement sensor with display

- Work Surface and Sensing Unit

- Aluminum profile Plate of 750mm x 550mm

- Sensing unit can be easily slide in T slots of Aluminium extrusions metal scale

- Work surface have the minimum dimension of 750mm x 500mm.

- Work surface is made up of Anodized Aluminium on which various sensors can be easily mounted.

INDUSTRIAL DIGITAL SENSOR TRAINER

UIT-05

- Trainer having control panel should be provided in MS Enclosure with sturdy table top flat panel.

- All input & output are terminated in 2mm banana connector; Provide 2mm banana cable for experiments.

- Power Supply Unit 230V/50Hz AC Socket.

- One Pilot Lamp to indicate Power input.

- 24V/2A Fixed DC Output

- NPN & PNP Input / Output for Proximity Sensor with Pilot Lamp

- DC Motor Unit

- 24V DC Motor with Speed Control Potentiometer

- One Pilot Lamp to indicate Power Input

- Counter Unit

- 230V/50Hz AC Socke

- Seven Segment Display to measure the event count.

- 1 No Inductive Proximity Sensor (M12)

- 1 No Inductive Proximity Sensor (M18)

- 1 No Fiber Optic Sensor with digital display & teach mode

- 1 No Diffusion Sensor PNP Type (M18)

- 1 No Through Beam Sensor PNP Type (M18)

- 1 No Reflect Sensor PNP Type (M18)

- 1 No Capacitive Proximity Sensor

- Work Surface and Sensing Unit

- Aluminum profile Plate of 750mm x 550mm

- Sensing unit can be easily slide in T slots of Aluminium extrusions metal scale

- Work surface have the minimum dimension of 750mm x 500mm.

- Work surface is made up of Anodized Aluminium on which various sensors can be easily mounted.